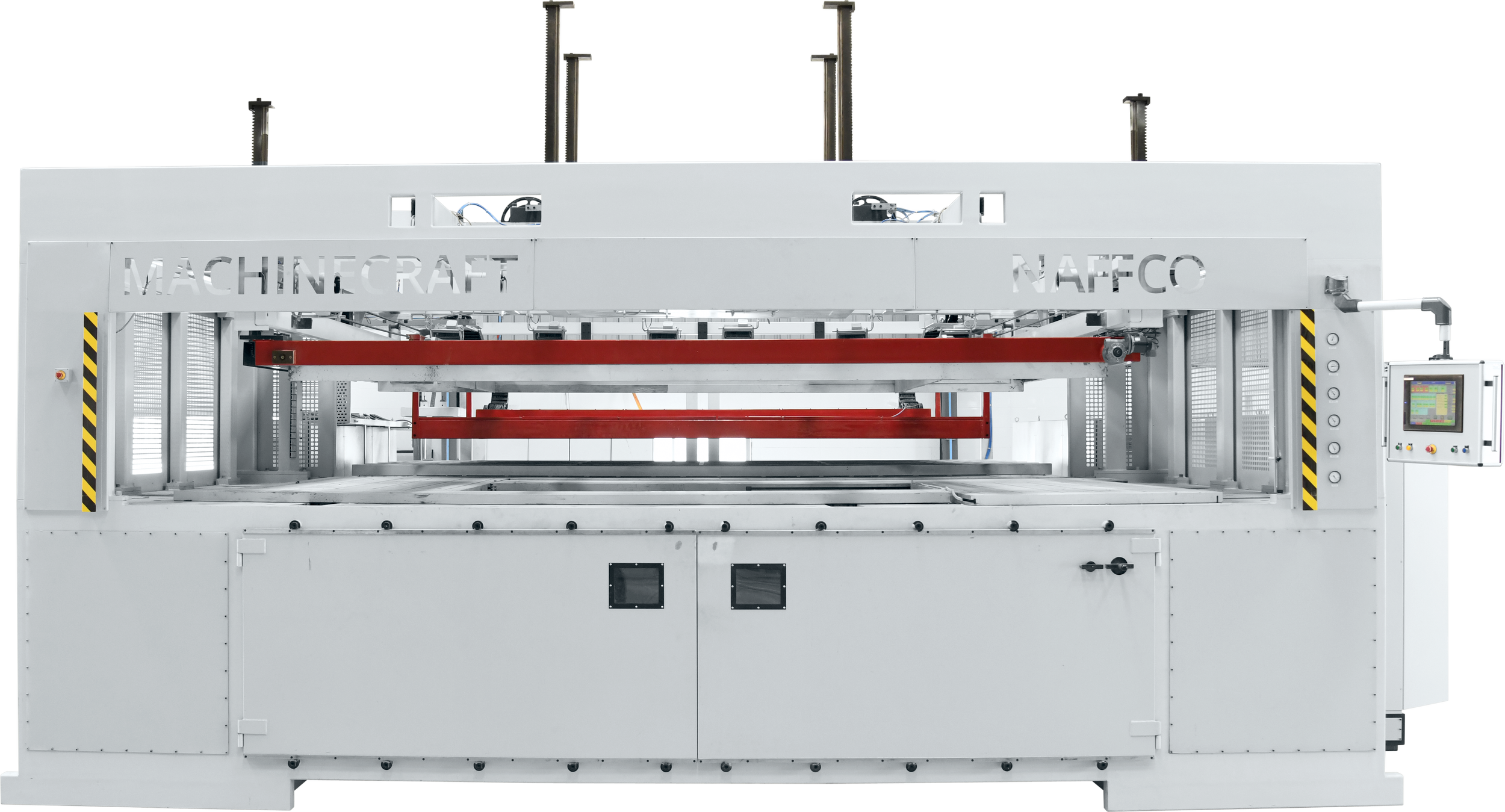

Cut Sheet Single Station Machine

PF1 Series

Closed Chamber Design | Tailor Made | Automation Options

Machinecraft is a specialist for manufacturing of custom built single station thermoforming machines with the European concept of closed chamber design to allow pre-blow bubble & zero sag control of thermoplastic sheets by blowing pulsating air in the air-sealed chamber - useful for getting close to an even final part thickness using the thermoforming process. Machines can vary from compact size 800x1000 mm upto XXL size of 5000x2500 mm. Machines can have automation options like sheet feeder or universal frames.

MACHINE FEATURES

Air-tight sealed closed chamber design to allow height adjustable pre-blow bubble & zero sag control of thermoplastic sheets by blowing pulsating air & controlling using light sensors - useful for getting close to an even final part thickness using the thermoforming process

Parametric machine design - based on customer specification sheet

Strong machine design - use of higher safety factor when it comes to selection of racks, linear guides, plates and other mechanical items on the machine for long life of the machine

Electrical panel designed with CE / UL guidelines and use of all components that are CE / UL certified

2-level safety in machine design - electric + pneumatic locking for all machine movements, light guards, safety locks, interlocks

Automation options like Automatic sheet loader & formed part unloader, Roll feeder, Universal frames for automatic aperture setting, Quick tool loading & clamping

Machine movements option of all electric servo motor driven

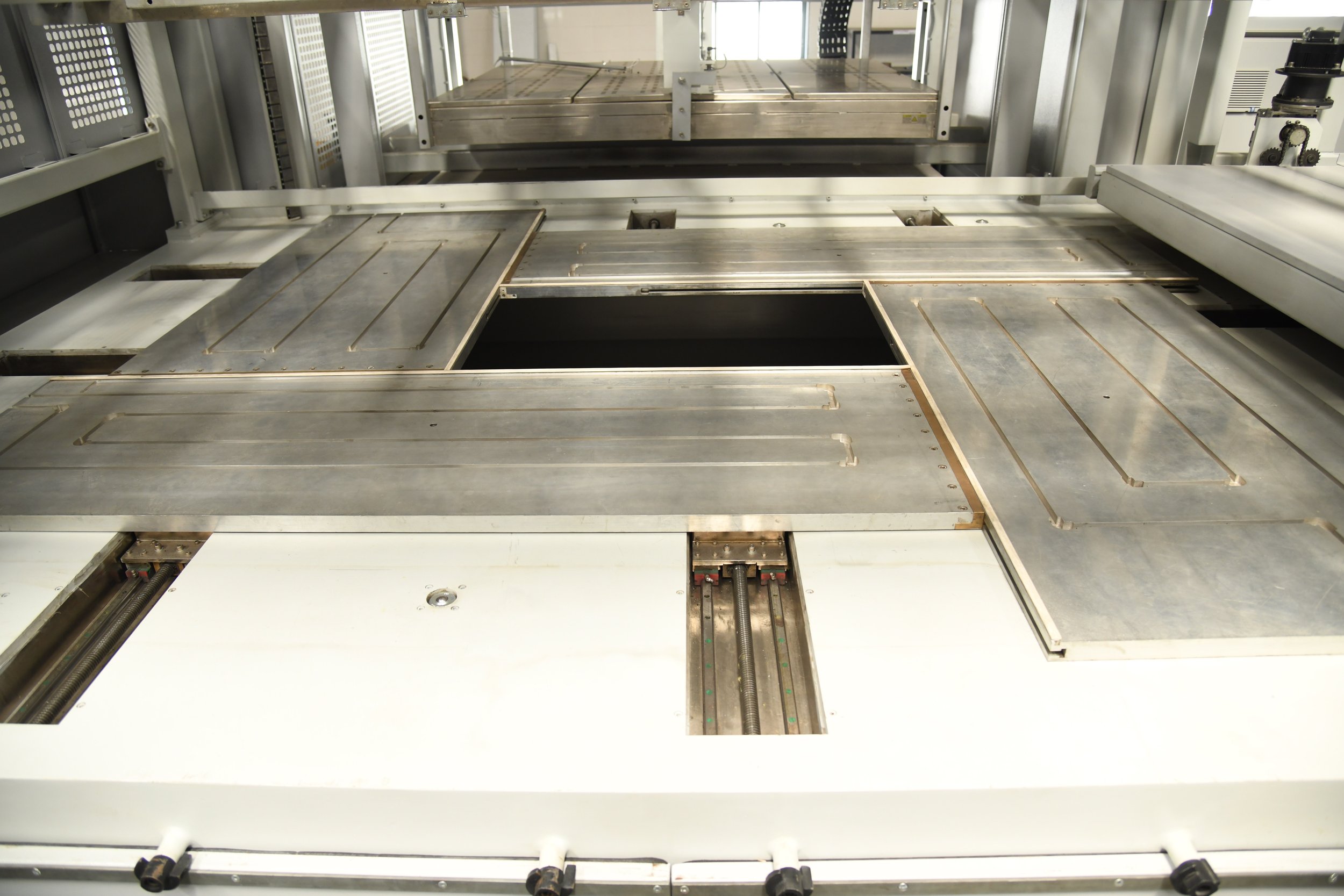

Unique chain type system for machine movements - easy to maintain if anything goes wrong - the sheet is not always the same - so sometimes things can go wrong and our system will be easy to get it back to running mode

Heater Oven Design - use of IR ceramic / quartz / flash elements - “Zone Control” or Individual heater control with sheet temperature detection using IR probe

HMI Design with operator in mind to allow setting of all parameters easily

TECHNICAL SPECIFICATIONS

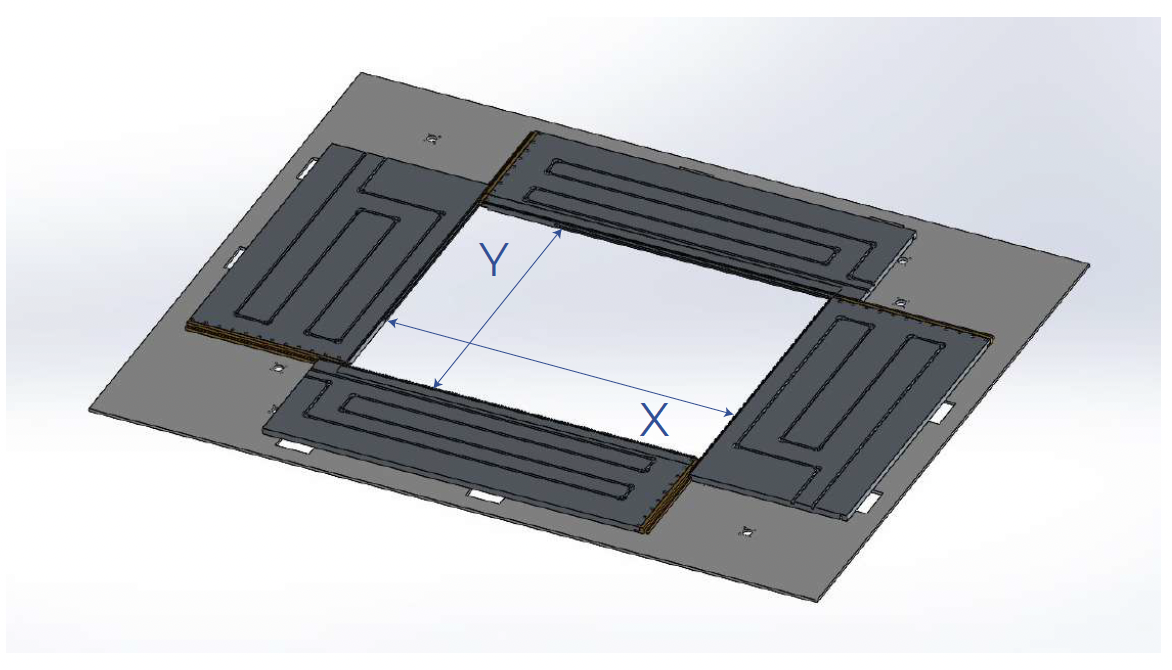

Max Forming Area (in mm)

X: 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 4500 | 4800

Y: 800 | 1000 | 1200 | 1500 | 2000 | 2500

Max Tool Height (in mm)

Z: 400 | 500 | 650 | 750 | 1050

All machines are custom built and tailor made as per customer’s requirement using parametric design

HEATER OVEN - ZONE CONTROLLED HEATING

Infrared (IR) Ceramic Type

Infrared (IR) Quartz Type - Energy Saving!

AUTOMATION OPTIONS

Automatic Sheet Loader & Part Unloader

Universal Frames for Automatic Aperture Setting

MAKE OF COMPONENTS

APPLICATIONS

Automotive - Passenger and Commercial Vehicles, Agriculture & Earth Moving Equipment, Lightweight Electric Vehicles, Interiors of Busses, Railway Interiors, Aircraft Interiors, Refrigeration Liners, Whitegoods, Renewables - Windmill Nacelle, Signages, Luggage, Sanitary-ware Bathtubs Jacuzzi Spas & Showerpanels, Chemical Toilets, Material Handling Pallets, Gym Equipment Covers, Motor Covers, Medical Device Covers, Skylights, Automats / Car mats, Mobile Robot coverings, Bedliner of Pickup Trucks ..

MACHINE EXAMPLES

READY TO SEND US AN INQUIRY?

MACHINE VIDEOS

Watch our video to see our customer’s testimonial about our machines & our service in Europe

Watch our video showcasing the all new 2024 all electric vacuum forming machine. The machine in the video is of max. forming area 1,600 x 2,100 mm and comes with features like universal aperture setting & autoloader. The client uses the machine to make parts for the bathtub industry with negative draw of 860 mm.

Watch our video showcasing the all new 2023 all electric vacuum forming machine for our client in Canada. The machine in the video is of max. forming area 4,800 x 2,500 mm and comes with features like universal aperture setting & easy tool loading. The client uses the machine to make parts for the signage industry.

Watch our video showcasing the all new 2022 all electric automatic vacuum forming machine for our client in Canada. The machine in the video is of max. forming area 1,500 x 2,000 mm and comes with features like universal aperture setting & automatic sheet loader. The client uses the machine to make parts for the signage industry.

Watch our video of thermoforming machine - all electric servo - with universal frames - making parts for the windmill sector. The video also shows the part being CNC trimmed using a 4-axis RT Series router from Machinecraft.

Watch our video showing our 2022 compact all electric thermoforming machine with max. forming area 800x1000 mm. The machine was made for our client in Sweden.

Watch our video showing a simple economic pneumatic driven vacuum forming machine with manual sheet loading & pre-drying oven for ABS interiors of trucks.

DOWNLOAD BROCHURE

Please fill the form the below to download the brochure

Machinecraft Technologies

505 Palm Springs, Link Road,

Malad W, Mumbai 400064, INDIA

Tel: +91-22-28817785

Email: contact@machinecraft.org